Manufacturing digital twin: how Lockheed Martin digitized factory operations

In industries with complex manufacturing processes, digital transformation is key in developing more efficient production operations that help organizations stay competitive.

A digital twin is a virtual model of a manufacturing system, including its processes, machines, and equipment. It brings together the physical and digital worlds to optimize the manufacturing process, identify supply chain or production bottlenecks or other blockers, and predict performance.

Lockheed Martin built an AI-enabled manufacturing digital twin with the help of graph technology to re-imagine the factory of the future and optimize workflow processes. Read on to see how they united multiple systems of record in one place for a more efficient, streamlined manufacturing process.

At Lockheed Martin, the Lockheed AI Center, or LAIC, works to transform their organization by applying innovative artificial intelligence, machine learning, and other commercial technologies across the board. LAIC has worked on projects ranging from building mission systems to aid in business decision superiority to enterprise projects to enabling the factory of the future.

Part of LAIC’s work has involved developing a manufacturing digital twin. This digital twin is now used for asset mapping and optimizing workflows. Let’s take a look at what that process looked like.

Lockheed Martin had been using different systems of record in its production lines, adopted over the course of many years. These included a precedence system to prioritize task completion, a manufacturing execution system (MES), a work crew planning system, and a system managing constraints - things that could slow down a build, like quality issues or a parts shortage.

These different systems each had their own interface. Navigating between them was inefficient, and teams sometimes spent more time planning than they did building. This created the risk of slower build times that could result in delayed delivery.

To manage these different systems, production teams relied on physical media: a white board with printouts of their precedence network, notes on constraints, etc. This physical system also created risk: it could be easily lost or destroyed and created the potential for communication breakdowns.

For LAIC, it was clear they needed to digitize the white board manufacturing teams were using. To do this, they uploaded the data from Lockheed Martin’s various systems into Neo4j graph database, which team members could access through Linkurious Enterprise graph visualization and analytics software as the front end.

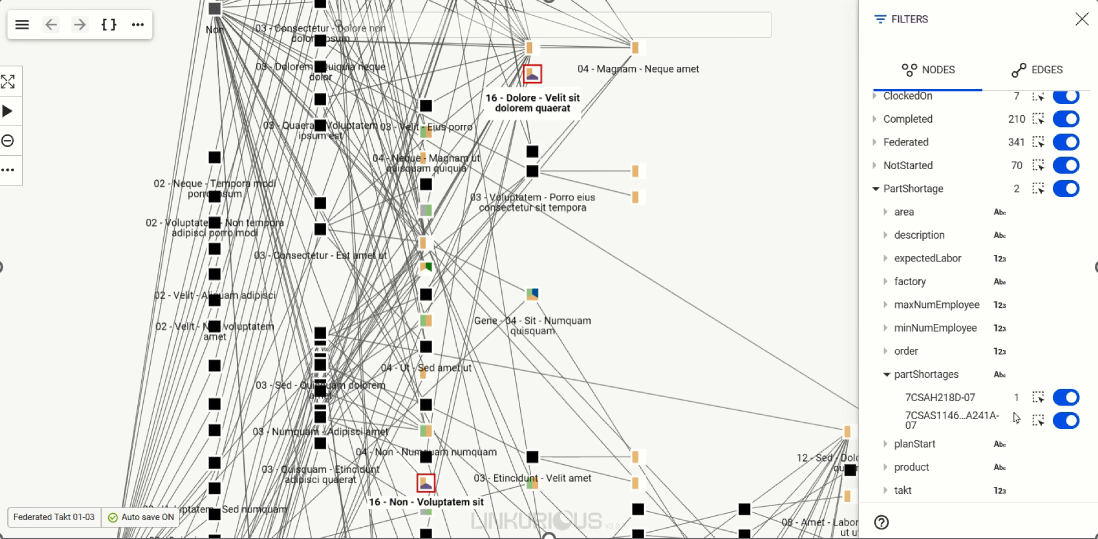

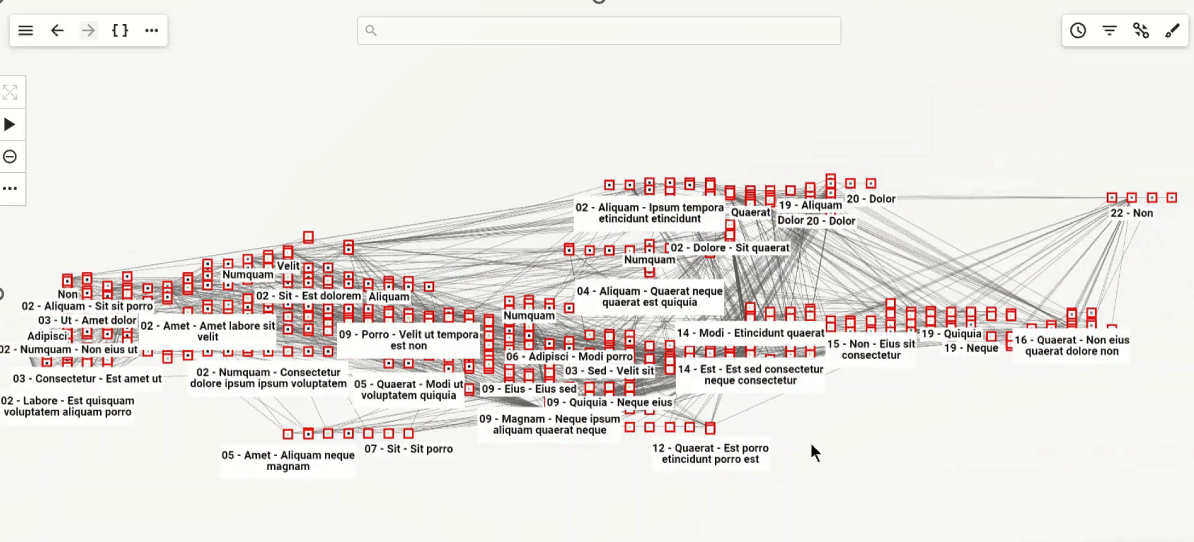

Within this system, LAIC built queries for the data that would turn up a whole precedence network as a graph visualization. In these visualizations, nodes represent individual tasks and edges represent precedence. In other words, they show which tasks must be completed before other ones, and how different tasks interact with each other.

They also built queries to look up things like missing parts or quality issues - constraints that can slow down a build. Queries also show where mechanics on the factory floor are working.

Visualizations make the new system easy to understand. LAIC set up color coding, which is explained in a legend on the screen. As the status of different tasks changes, the colors change in real time, making it easy to track progress at a glance.

Linkurious Enterprise has facilitated the building and use of Lockheed Martin’s manufacturing digital twin. The software has enabled the team to set up template queries, define groups to control who has access to which pieces of information, and to set up default styles and layouts. Linkurious was even able to develop a left to right layout for Lockheed Martin to facilitate adoption of the new system.

Labels within Linkurious Enterprise communicate the state of tasks: their progress, workability, and activity. Properties show details like task identity, start and finish times, mechanic assignments, and constraints. And, using custom actions in Linkurious Enterprise, the team can link out to other pages or APIs when they need to give more context to a given task or piece of information.

Graph has proven to be a living structure, adapting to the needs of the team. It has also been a major time saver. Previously, supervisors needed 4 or 5 windows open on their screens at any given time. Teams were also losing time between shifts. And, new supervisors had a host of tools to learn. Now, multiple systems are centralized into a single tool.

Graph visualization and analytics also gives teams at Lockheed Martin the information they need, when they need it. They can zoom into any part of the graph they need to examine more closely. They can also query the graph to quickly see downstream dependencies, anticipating potential blockers and bottlenecks before they cause problems.

In a recent webinar, Travis Jefferies, Staff AI Research Engineer at Lockheed Martin, tells the story of how Lockheed Martin is using Neo4j and Linkurious to digitize operations on manufacturing lines critical to 21st century security.

Learn about the whole process by watching the replay here.

A spotlight on graph technology directly in your inbox.